Hydrated Lime (Calcium Hydroxide – Ca(OH)₂)

Other names: Slaked Lime, Lime Putty, Milk of Lime, Mason Lime

Size: 200–325 mesh

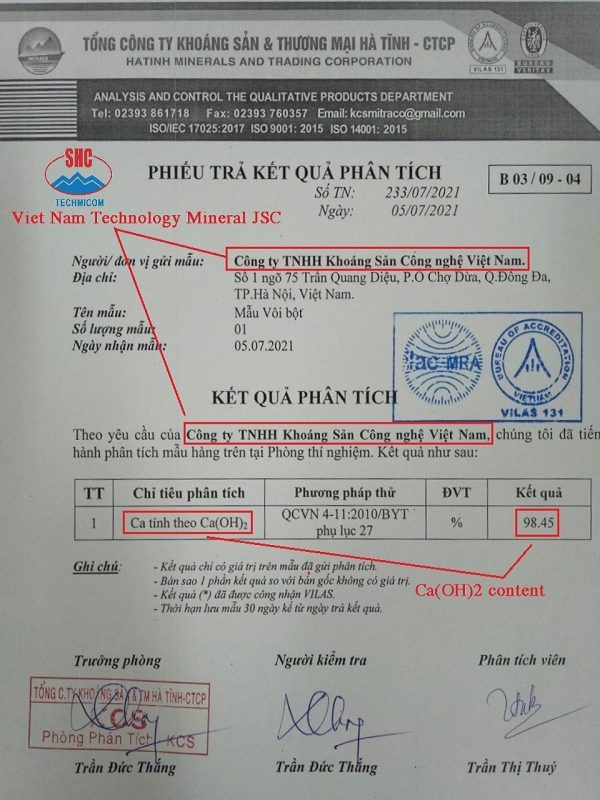

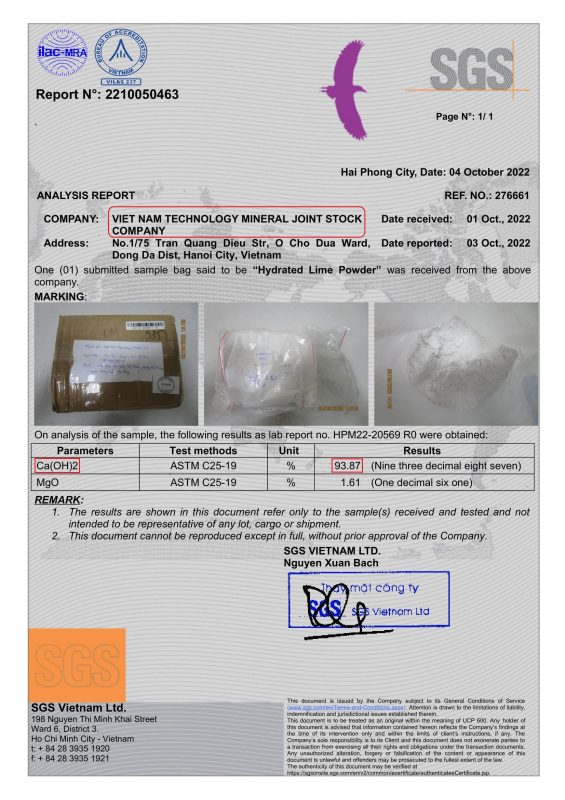

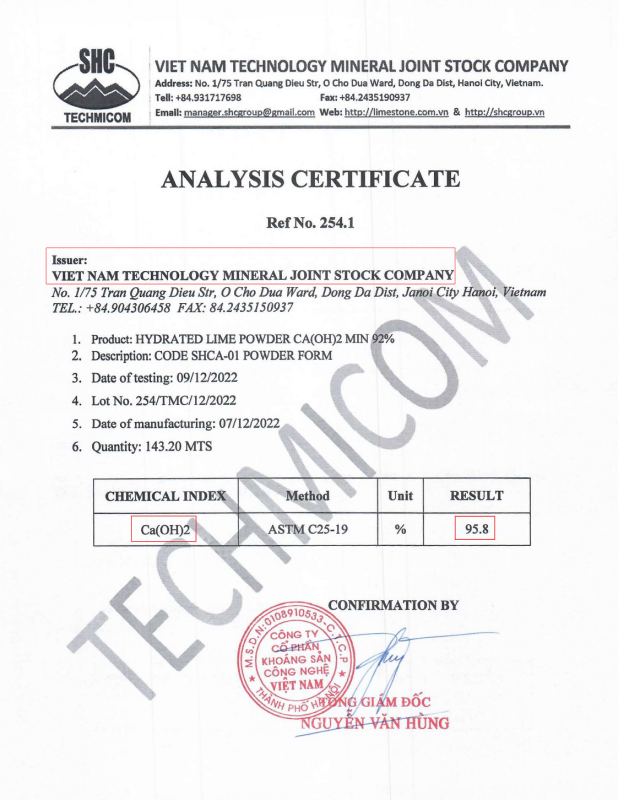

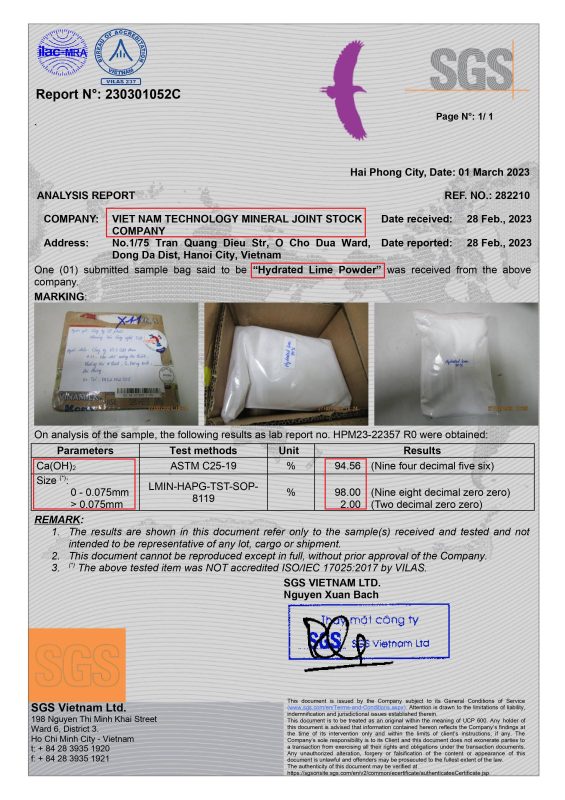

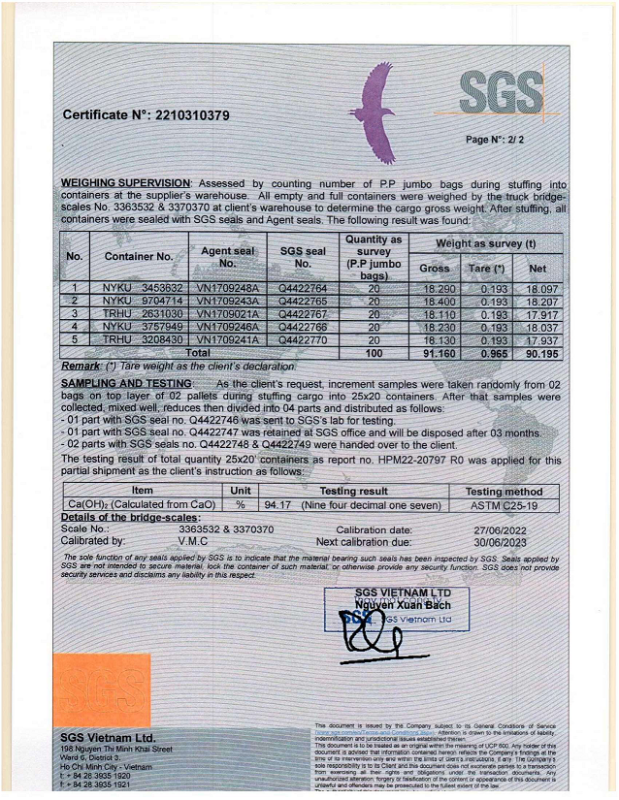

Manufacturer: Vietnam Technology Mineral JSC

Description:

Hydrated lime is produced by mixing quicklime (CaO) with water in a process called hydration or slaking. The reaction is:

CaO + H₂O → Ca(OH)₂ + Heat

This exothermic process forms calcium hydroxide — a fine, white powder that is less reactive than quicklime but retains excellent adhesive and plastic properties, making it valuable in construction and industrial applications.

Compared to quicklime, hydrated lime is:

-

Safer to handle

-

Easier to store and transport (bulkier form)

-

Longer shelf life when stored properly

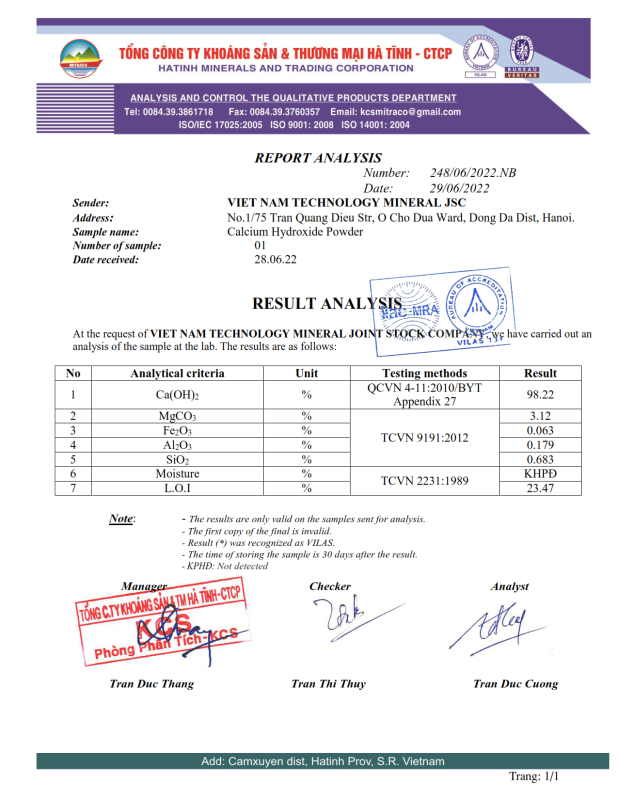

Key Specifications:

-

Ca(OH)₂ content: ≥ 85–90% (≥ 90% for high-quality grade)

-

Fineness: 200–325 mesh for superior workability and reactivity

-

Moisture content: ≤ 10–12% for optimal shelf life

-

Impurities: ≤ 1–2% each of magnesium, silica, alumina, and iron

-

Consistency: Stable fineness, moisture, and chemical composition across batches

-

Density: High bulk density for greater active material per unit volume

-

Activity: Strong carbonation capacity in mortar/concrete, ensuring high alkalinity

-

Color: Pure white without gray or off-tint, indicating purity and complete hydration

-

Setting time: Approx. 2 weeks for lime putty, 1 month for powder form

-

Packaging: Airtight to prevent CO₂ absorption and preserve quality

Applications:

Hydrated lime is widely used in:

-

Construction: Mortar, plaster, whitewash, soil stabilization

-

Water & Wastewater Treatment: pH control, softening, impurity removal

-

Chemical Industry: Production of chemicals, neutralization of acids

-

Paper & Pulp: Causticizing in kraft process

-

Environmental Uses: Flue gas treatment, waste stabilization

-

Agriculture: Soil conditioning, pathogen control, odor management

Production Advantage:

Our hydrated lime is produced from premium quicklime using efficient hydration technology, strict quality control, and fine grinding to ensure maximum purity, whiteness, and performance in all applications.