Quick Lime Lumps 0–25mm (Calcium Oxide – CaO)

Other names: Burnt Lime, Calcined Lime, Unslaked Lime

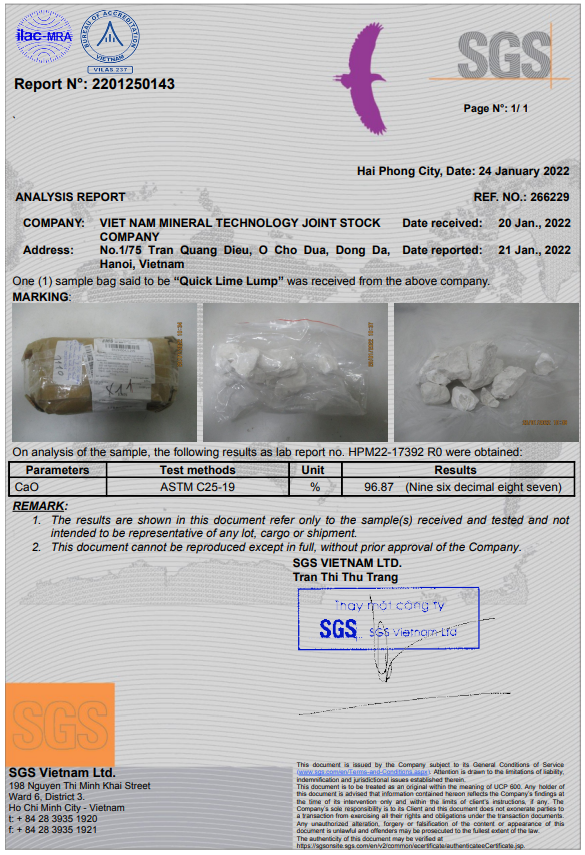

Manufacturer: Vietnam Technology Mineral JSC

Description:

Quick Lime Lumps 0–25mm are produced by calcining selected high-purity limestone (CaCO₃) in modern rotary kilns at high temperatures. This process drives off carbon dioxide (CO₂) to form calcium oxide (CaO):

Reaction: CaCO₃ → CaO + CO₂

This product is supplied in lump form with particle sizes from 0 mm to 25 mm, ideal for various industrial and chemical applications requiring strong reactivity and controlled handling. When mixed with water, it reacts exothermically (slaking of lime), releasing significant heat. With a high alkaline pH (~12.5), it is highly caustic and must be handled with proper safety precautions.

Key Specifications:

-

CaO content: ≥ 90% for premium-grade quality

-

Size range: 0–25 mm (screened and graded)

-

Moisture content: ≤ 1–2% to ensure optimal reactivity

-

Impurities: MgO ≤ 2.5%; negligible heavy metals (Pb, As)

-

Density & Consistency: Uniform lump quality, density, and burning degree

-

Reactivity: Fast, exothermic reaction upon slaking; ideal setting time ~24 hours

-

Storage stability: Maintains performance for 6–12 months with proper storage

-

Source traceability: Produced from carefully selected limestone with consistent kiln control

Applications:

Quick Lime Lumps 0–25mm are widely used in:

-

Metallurgy: Steel refining, non-ferrous metal smelting

-

Construction: Soil stabilization, mortar production, hydrated lime manufacturing

-

Water Treatment: pH adjustment, softening, removal of impurities

-

Chemical Industry: Production of calcium carbide, soda ash, bleaching powder

-

Paper & Pulp: Kraft process causticizing and pulp digestion

-

Environmental Uses: Flue gas desulfurization, acidic waste neutralization

-

Agriculture: Soil conditioning, pest & odor control

Production Advantage:

Manufactured in modern rotary kilns for consistent burning, high reactivity, and uniform lump size distribution.

Technical Data Sheet

|

No |

Property |

Unit |

Result |

Testing Method |

|

1 |

CaO |

% |

90 MIN |

TCVN9191:2012 |

|

2 |

MgO |

% |

1.92 |

TCVN9191:2012 |

|

3 |

Fe2O3 |

% |

0.09 |

TCVN9191:2012 |

|

4 |

Al2O3 |

% |

0.05 |

TCVN9191:2012 |

|

5 |

SiO2 |

% |

0.2 |

TCVN9191:2012 |

|

6 |

S |

% |

0.05 |

TCVN9191:2012 |

|

7 |

L.O.I |

% |

3.6 |

TCVN2231:1989 |

|

8 |

Slaking point |

minute |

2-5 |

TCVN2231:1989 |

|

9 |

Color |

|

Milky white |

- |

|

10 |

Moisture |

% |

0.2 |

- |

|

11 |

Size: 10-80MM |

% |

95 |

- |